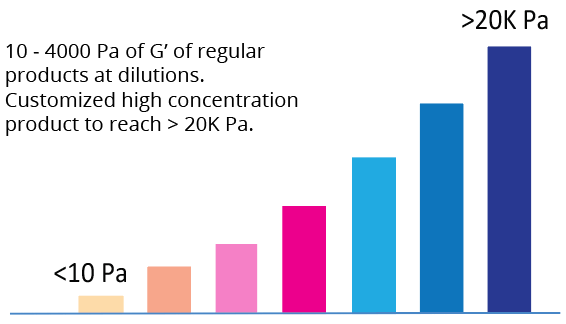

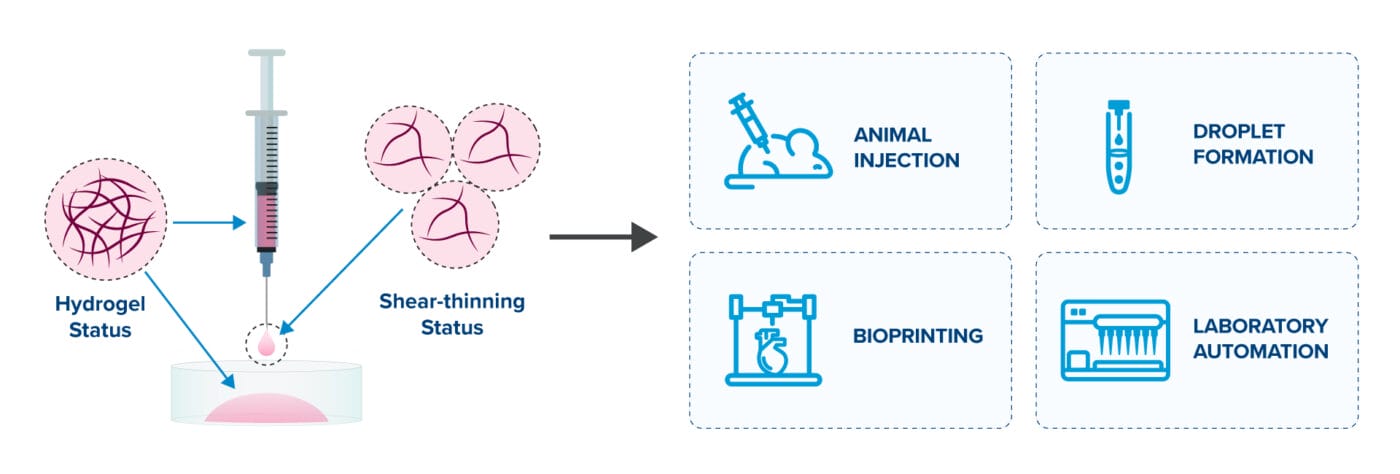

Unique Injectable Properties of VitroGel®

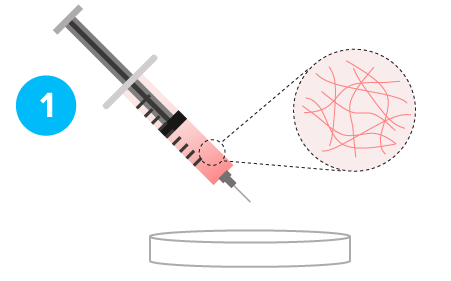

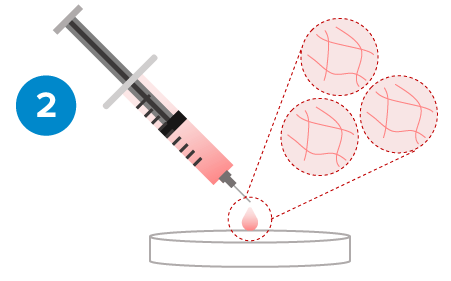

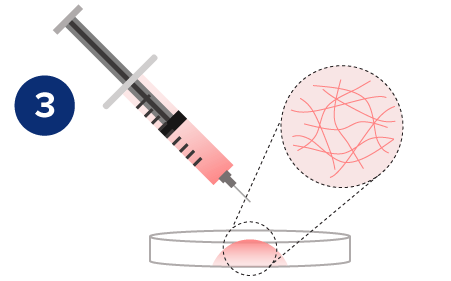

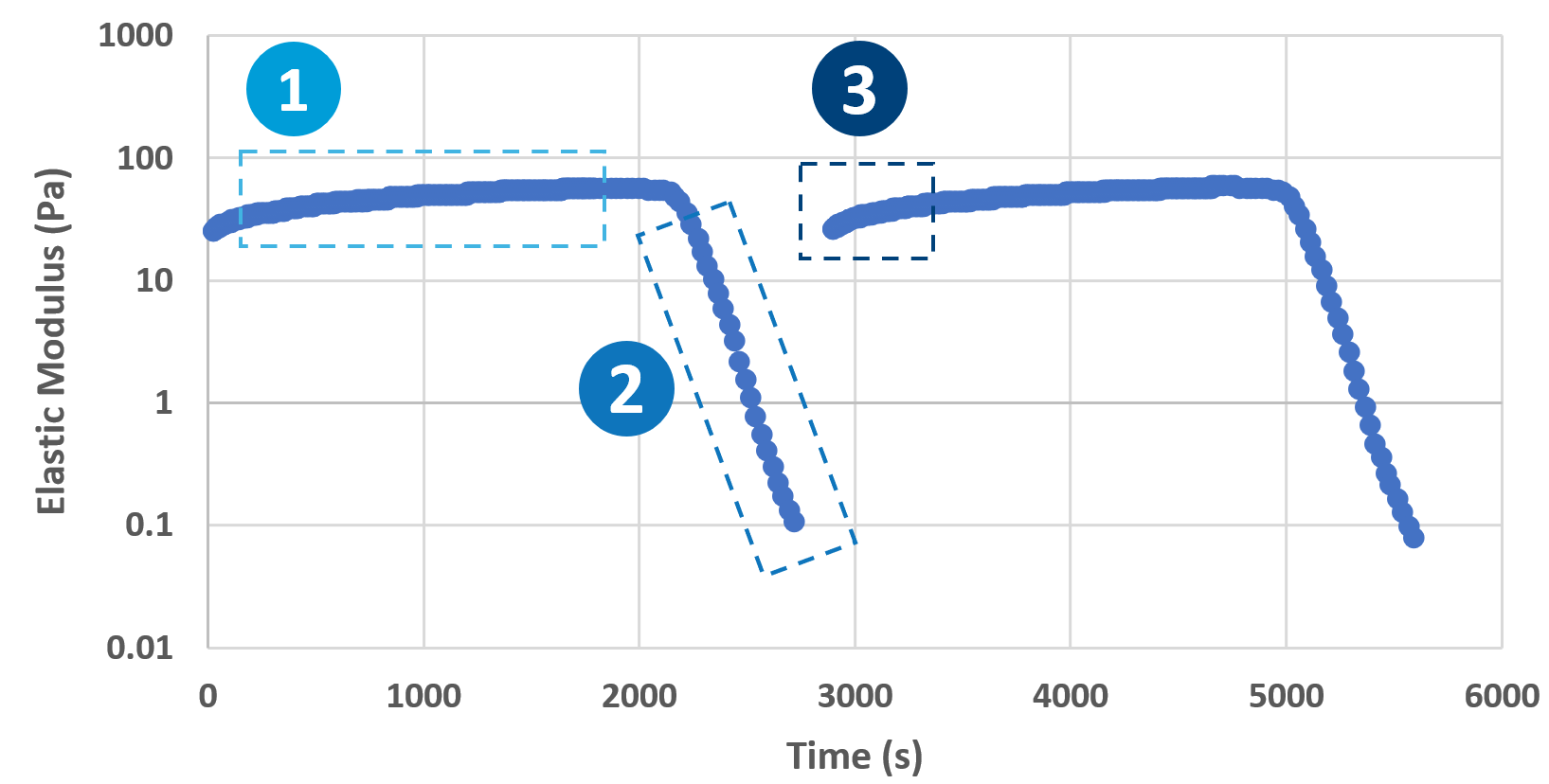

From hydrogel to soft hydrogel back to hydrogel, the VitroGel® hydrogel system has unique shear-thinning and rapid recovery rheological properties for long-term injectable status ideal for animal injection, bioprinting, droplet formation, and lab automation.

Extremely smooth injectability for versatile applications

Room temperature stable for sample preparation and operation.

No needle/tip clogging issue that is prone to animal-based ECM.

Long-term injectable status. No rush for injection for stress-free operations.

Synthetic, xeno-free system for consistent data and biomedical potentials.

With the unique injectable property and above features, VitroGel® can be used for in vivo cells/drug delivery with excellent retention, bioprinting, droplet formation, and laboratory automation.

Animal Injection

Easy room temperature operation

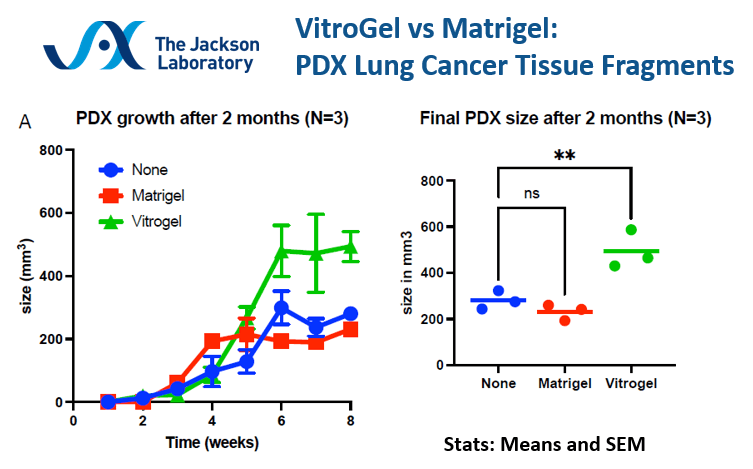

Excellent for both PDX and CDX models

Maintains homogeneous cell suspension

Trusted by leading global CROs and Pharma

Excellent cell retention & growth kinetics

Supports most major cell types with 100% growth rate

VitroGel® is ideal for animal injection due to its injectability, biocompatibility, consistent viscosity, and mechanical properties that ensure smooth and reproducible injections. Its xeno-free composition reduces immune reactions and mimics the natural extracellular matrix to support cell growth and viability.

With its unique injectable property, cells or compounds can be pre-mixed with VitroGel® and maintained as a homogeneous mixture in the injectable state for in vivo applications.

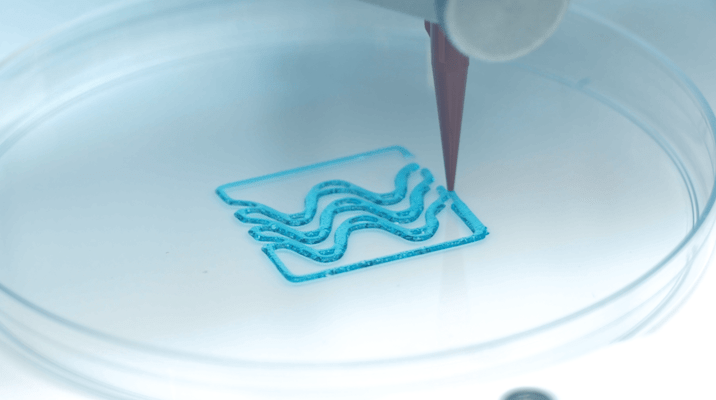

Bioprinting

VitroINK® – A New Generation of Bioinks

No UV Crosslink

No Heat Curing

No Chemical Crosslink

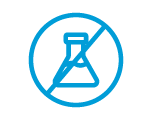

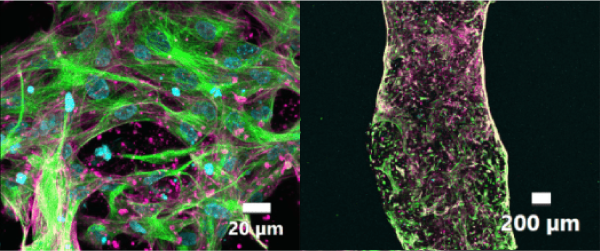

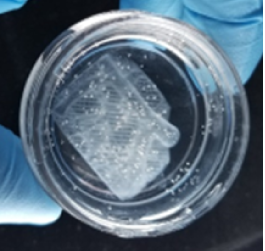

VitroINK® is ideal for bioprinting due to its tunable viscosity and mechanical properties, which ensure precise and consistent extrusion through bioprinter nozzles, allowing for the creation of intricate and stable 3D structures.

Its biocompatible, xeno-free composition supports cell viability and proliferation, essential for producing functional tissue constructs. Additionally, VitroINK® bioinks are room temperature stable, making them much easier to handle. Cells can be either pre-mixed or mixed directly with the bioink by using a dual syringe system. Multiple biological functional components can be incorporated with VitroINK® for different applications.

Works with any

Works with any

extrusion-based bioprinter

The unique mixing device ensures no air bubble when mixing cells with VitroINK®

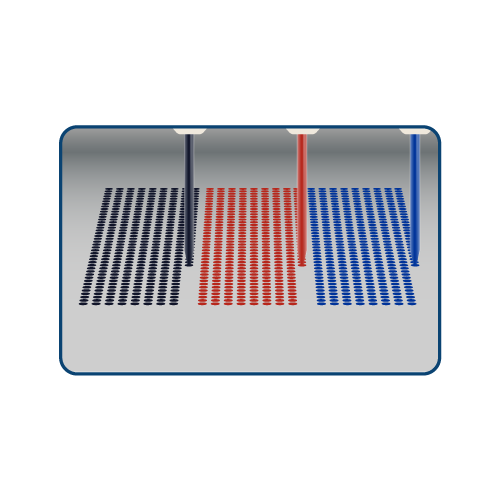

Excellent extrusion uniformity and shape fidelity

Bio-functional formulation for cell-matrix interactions

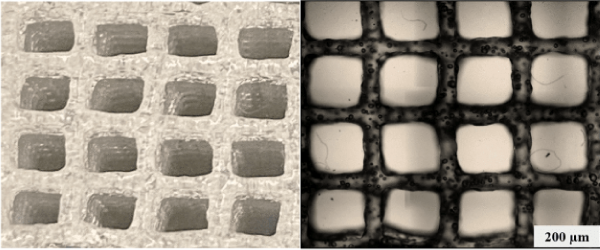

High cell viability after printing

Supports FRESH printing

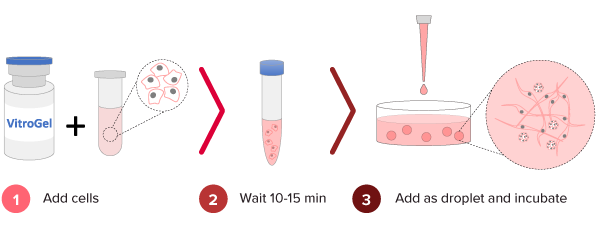

Droplet Formation

Crosslink with cell medium, No oil needed

Easy Setup – Work w/ or w/o microfluidic chips

Tunable Hydrogel for adjustable droplet size

High Cell Viability & Easy Cell Harvesting

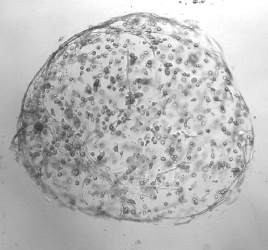

VitroGel® hydrogel is ideal for droplet formation because its unique hydrogel properties enable precise control over gelation, allowing it to form stable and uniform droplets.

The hydrogel’s mechanical characteristics can be finely tuned, ensuring consistency and reproducibility in droplet size and shape. Additionally, its biocompatible and xeno-free composition supports the encapsulation and viability of cells or biomolecules within the droplets, making it suitable for various applications, including 3D cell culture, drug screening, and regenerative medicine.

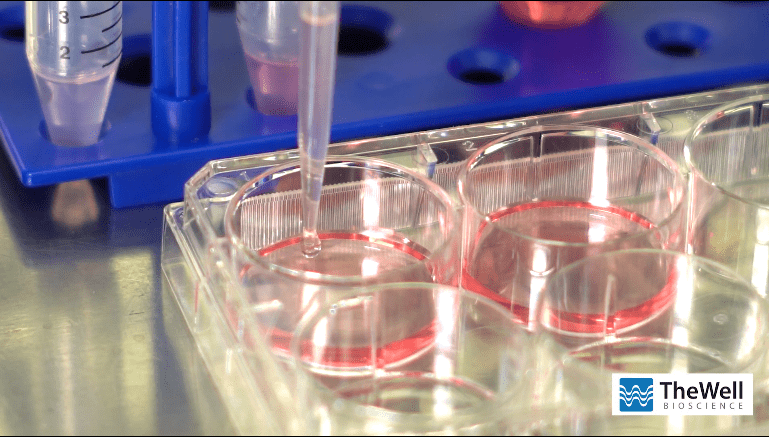

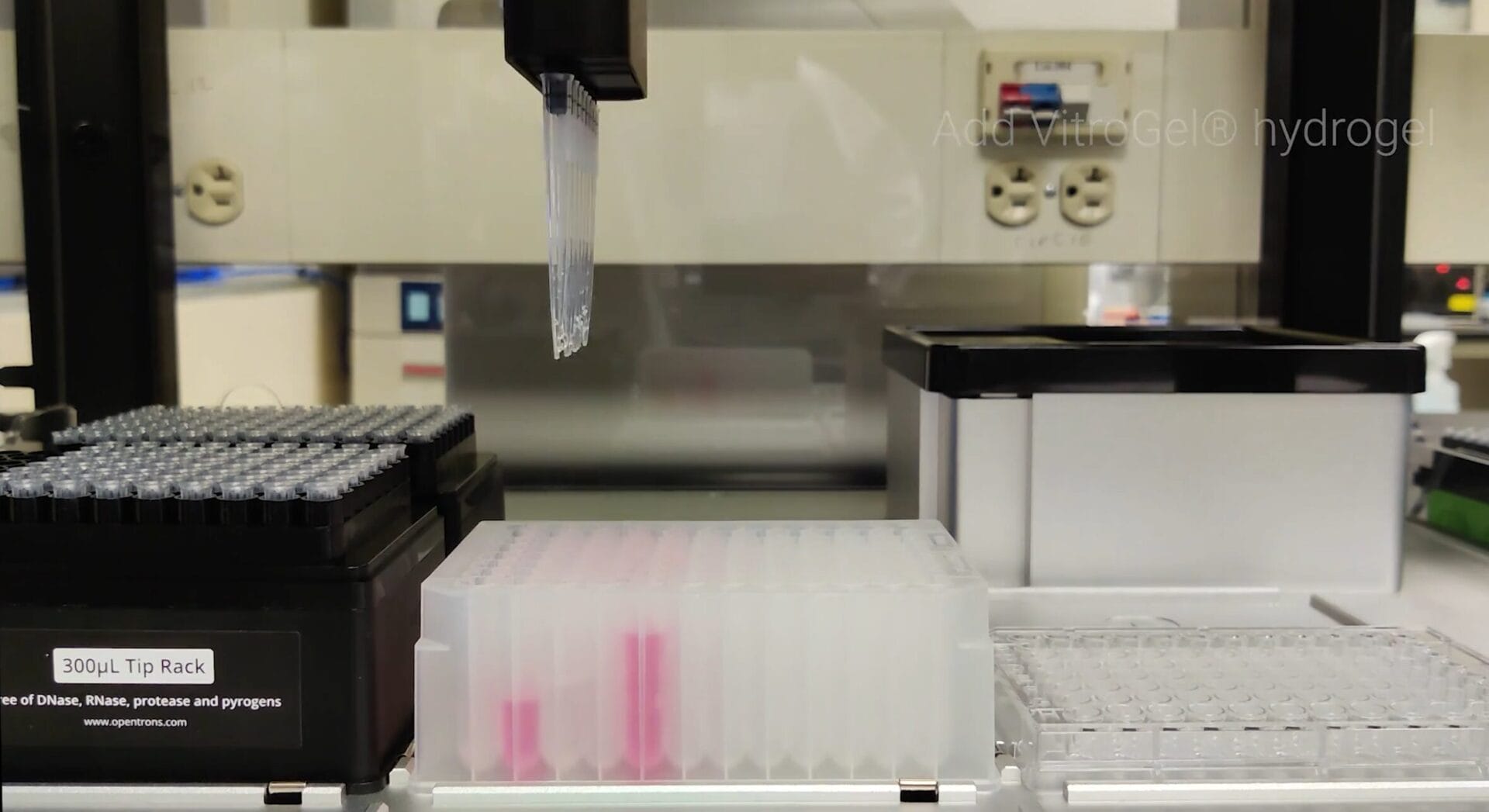

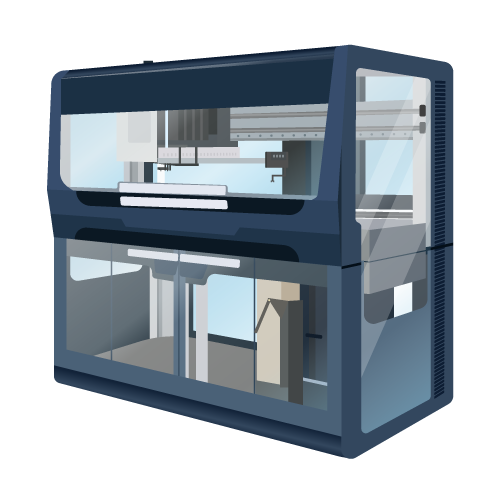

Lab Automation

Easy-to-use, room temperature operation

Applicable for both VitroGel® and VitroINK®

Works with all types of lab automation equipment

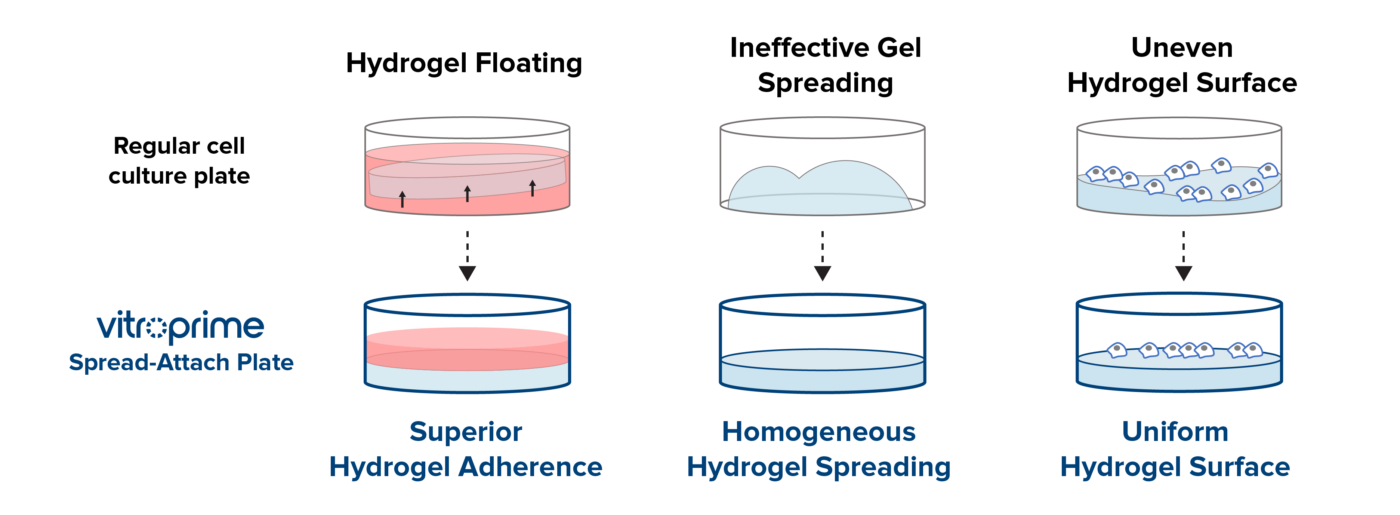

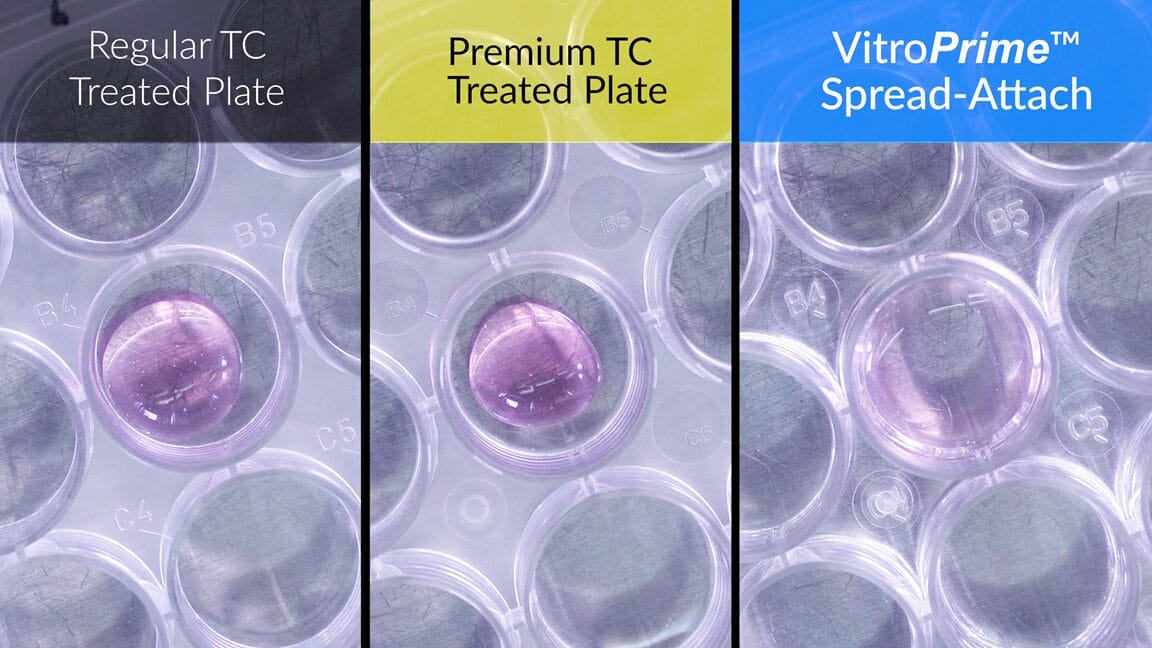

Excellent for VitroPrime™ Spread-Attach Plate

VitroGel® hydrogel is room temperature stable, and its unique shear-thinning and rapid recovery rheological properties allow for easy dispensing in laboratory automation and high throughput applications.

VitroGel® works with all types of lab automation equipment

Automatic

multiple-channel pipette

Bench-top

liquid handling machine

Fully automated

liquid handling system

Microarray: non-contact

dispensing system

VitroPrime™ Spread-Attach Plate: excellent for hydrogel lab automation